Motor brushes are an important component of stairlift systems, all battery-operated stairlifts use motor brushes that need to be checked for wear. This is because the motors used in stairlifts are typically DC motors, which rely on brushes to conduct electrical current between the batteries and the rotating parts of the motor. The motor brushes are spring loaded and transfer voltage by pushing against the motor’s armature, turning the motor for movement when a toggle switch is pushed or a remote control button is used.

Stairlifts use DC motors because they are efficient and compatible with batteries which are a proven and safe means to power a stairlift. Motor brushes wear down over time due to friction with the motor’s commutator and will need to be replaced eventually. The lifespan for these brushes ranges depending on the amount of use, length of stairs, and motor design but typically is from 5 to 10 years.

Signs of Wear

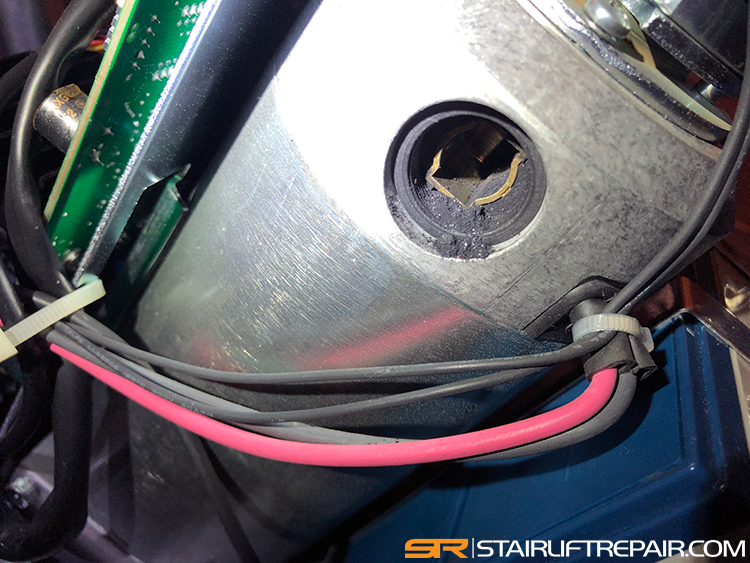

When motor brushes need to be replaced there will be a few signs to watch for while the lift is running. The most common sign is intermittent operation or difficulty starting the stairlift. This symptom is something that can also be caused by several other issues and is why motor brush problems can be tricky to diagnose. The second sign is unusual noises, such as grinding or humming sounds. These sounds are typically caused by a piece of the brush that has broken off and is caught internally in the motor casing. The third sign is reduce performance where the lift runs slower or feels less powerful while operating. This is caused by a loss of a clean contact between he motor and the brush after significant wear.

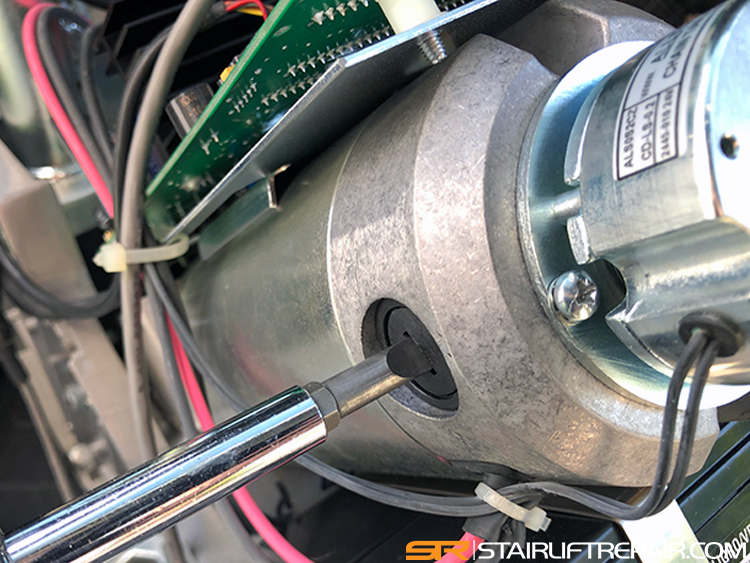

Maintenance Recommendation

This is why we recommend having the motor brushes inspected as part of your stairlift’s routine maintenance. These small yet critical components play a vital role in providing smooth and reliable operation of your stairlift. During a maintenance check, a qualified technician can check the condition of the brushes and other motor components, cleaning or replacing them as needed. Regular inspections extend the lifespan of the brushes and also help prevent potential issues before they become costly repairs.