Understanding Stairlift Drives

Stairlift drives are the main component on a lift that carries the load and moves the lift up and down stairs. Stair lift drives are manufactured in a few different types and have different features. Here are the four main types of stairlift drives.

Rack and Pinion Drive

The most commonly used drive is called a rack and pinion. This drive uses a gear (pinion) attached to a gearbox and 24 volt DC motor that moves along a toothed rail (rack). This type of drive is used by Acorn, Brooks, Bruno and Handicare stairlifts. The pros of this type of drive are they usually have smooth and reliable operation, they are also relatively quiet. The drawbacks are they can require more maintenance due to the need for regular lubrication.

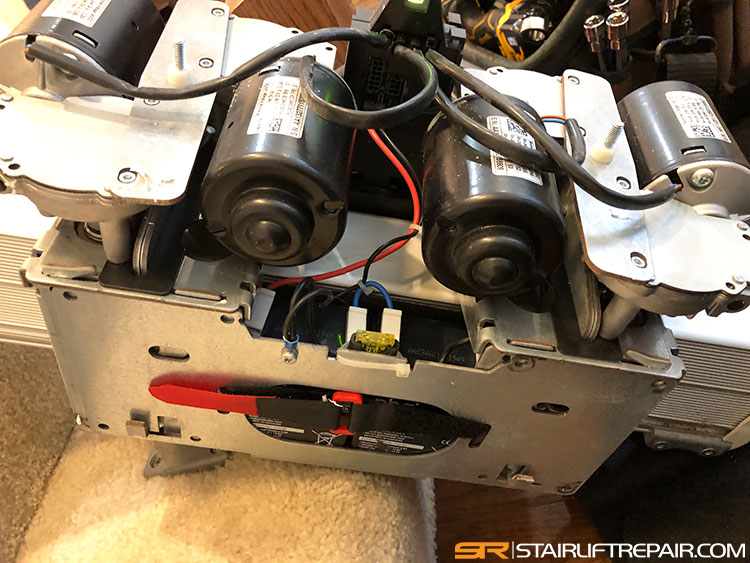

Worm Gear Drive

This drive uses a worm gear that rotates on a matching track to move the lift. This drive is used on the Harmar Pinnacle and Amerglide Rave stairlifts. The pros of this drive are reliable operation for heavy use. This design also provides high torque for higher weight capacity and requires less maintenance. The only con that we’ve encountered is they can be slightly louder than a rack and pinion drive.

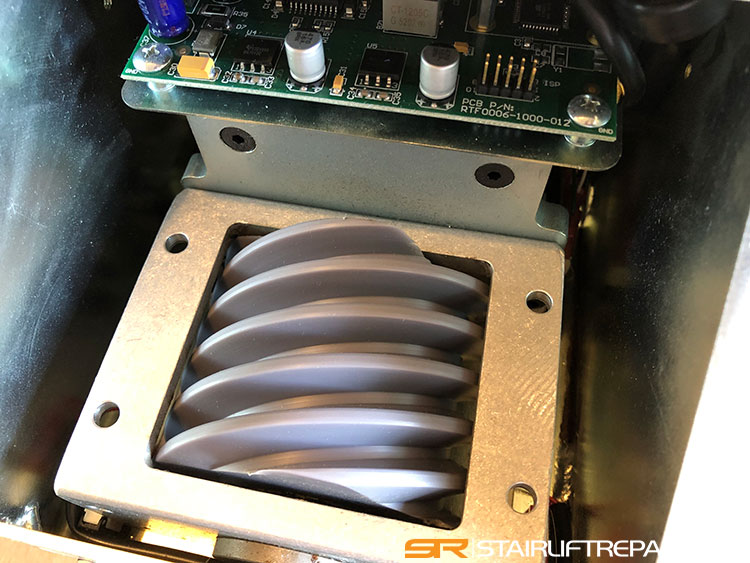

Friction Drive

The friction drive uses friction between the drive and the track to move the lift. The friction drive system is relatively new to the stairlift market and is exclusive to the Handicare Model 1100. We would describe this system as having smooth and quiet operation. The drive mechanism operates without the need for traditional gears, chains, or belts, making it a low-maintenance option. The drives design helps it remain clean, as there are no exposed parts that can attract dust and debris.

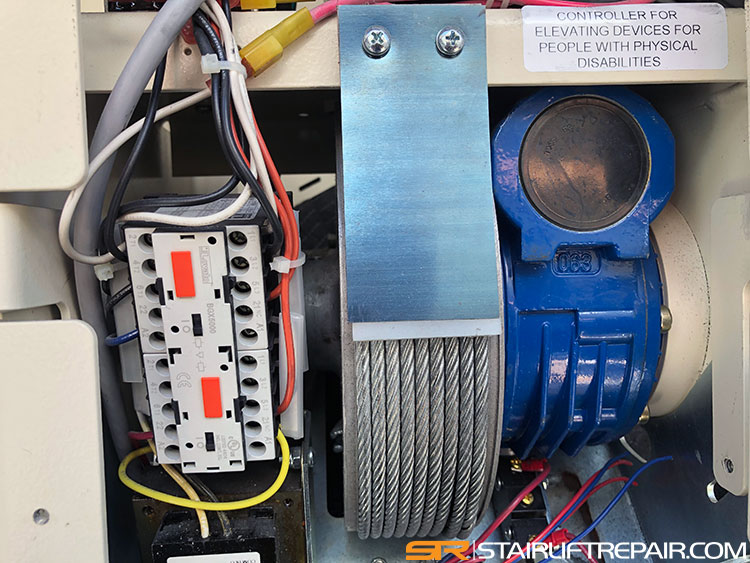

Cable Drive

This drive operates using a cable that pulls the lift along the track as it winds around a steel drum attached to a motor. The pros of a cable drive are they are usually the least expensive. The drawbacks are the cable can become worn over time and be more problematic with the cable safety monitoring system.

When choosing a stairlift, it is important to consider factors such as the user’s weight, the type of staircase, the desired noise level, and the maintenance requirements. Consulting with a professional stairlift company can help determine the best drive mechanism for a specific situation.