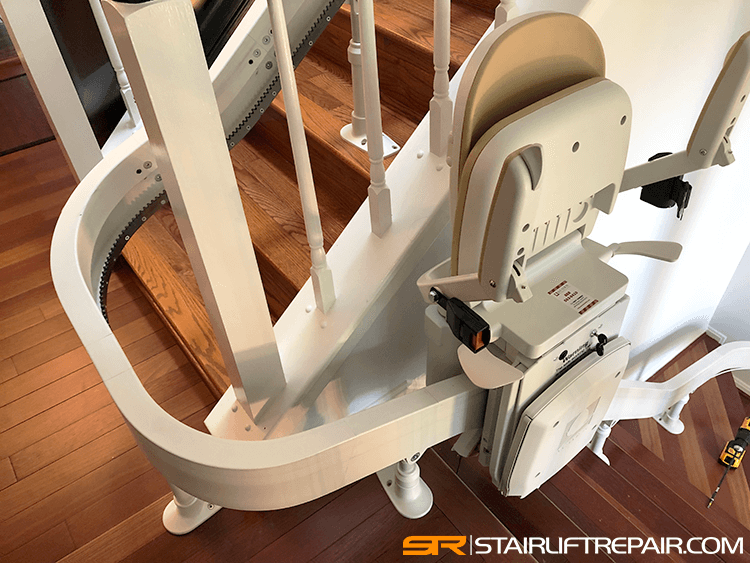

The Acorn 180 curved stairlift is a customizable lift made to fit a wide variety of stairs. The track is manufactured in modular rail sections allowing for quick installation times.

How the Acorn 180 works

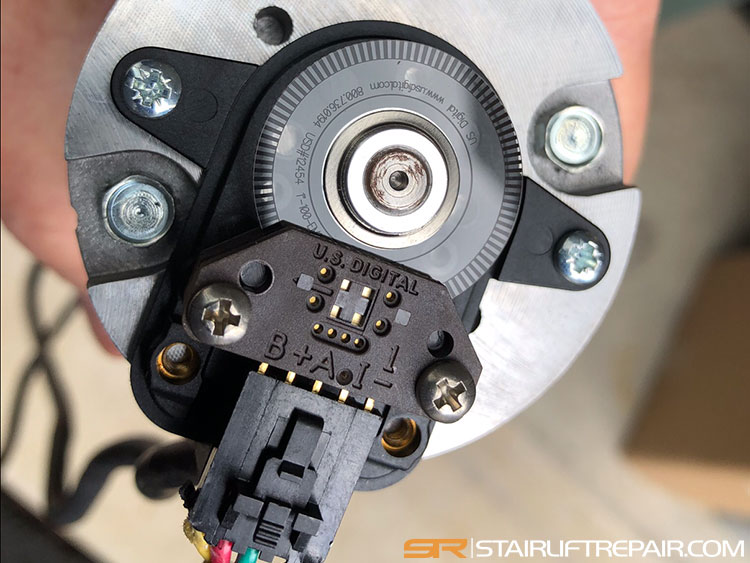

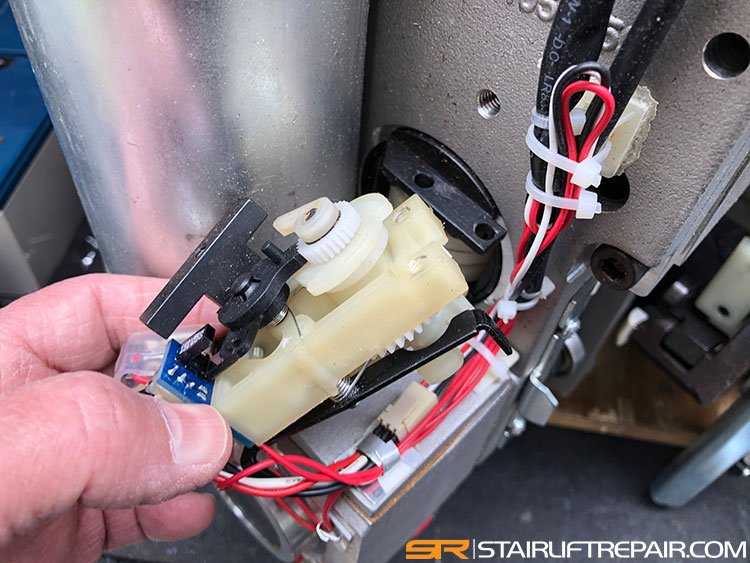

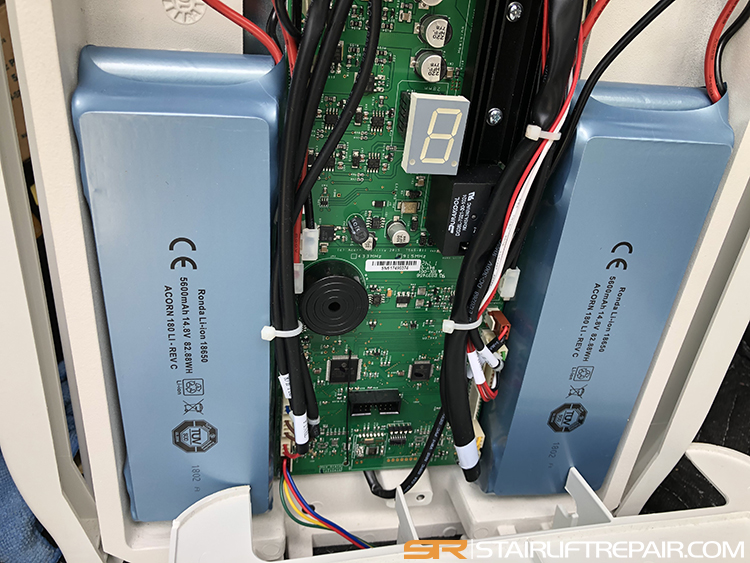

The lift is powered by two 14.8-volt Lithium Ion battery packs that drive the lift along its track. The battery packs are designed and engineered specifically for the Acorn curve lift. Since this lift is built on a single rail system, it also utilizes a second leveling motor to maintain the seat in an upright position. The controller reads data from an encoder on the drive motor shaft to make adjustments to the seat level while traveling on inclines and around corners.

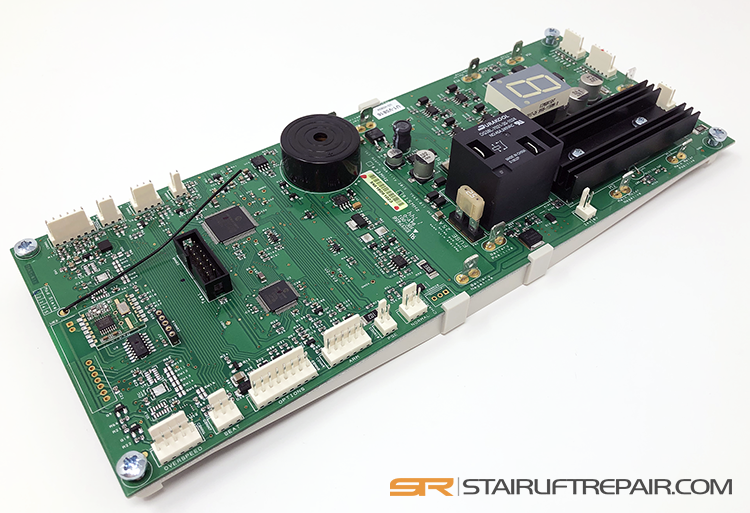

Because of this, the lift has to be programmed to match the track when installed, or if it powers off for any reason and the lift is moved manually with the hand crank. Also, in some cases, when changing batteries. Programming of the lift should only be done by a technician who is trained and experienced with the Acorn curved 180 T565 PCB control board program process. The Acorn 180 curved stairlift operates off the control board shown in this picture.

The J3 code and more

Here we have a J3 code with the lift in self-leveling safety mode and traveling in slow speed. This happens when the lift is out of program or has just been programmed and finding its position on the track. If the lift were to go around a corner or on an incline it could possibly cause a seat tilt motion and should not be used until corrected. The J3 code can appear if the batteries have died, have been replaced, or complete power failure from a PCB fault.

Acorn 180 Error Codes & Troubleshooting

The following is a list of error codes and is for information only. The Acorn 180 is a complex lift and should only be serviced by a professional stairlift mechanic.

E = ERROR CODES

Some of the E codes can be used for basic issues and Acorn 180 stairlift troubleshooting, others will require a technician. Under no circumstances should anyone other than a trained technician install, adjust, or service any mechanical or electrical device on this equipment.

E1 – Footrest switch DOWN side, the directional safety switch has been activated.

E2 – Also the footrest switch but on the UP side, the directional safety switch has been activated.

E3 – The footrest switch under-pan DOWN side safety switch has been activated.

E4 – The carriage edge switch DOWN side safety switch has been activated.

E5 – The carriage edge switch UP side safety switch has been activated.

E6 – Seat is not swiveled and in the locked operating position

E7- Internal batteries are low. The lift may have been left off the charge contacts or unplugged.

E8 – The lift has overheated and won’t operate. The lift may operate after cooling down or the main PCB will need to be replaced.

E9 – Encoder faults on either the drive motor or leveling motor. The PCB is not receiving information from the encoder.

F = FAULT CODES

F1 – Relay fault controller may need to be reset or replaced.

F2 – Brake fault voltage to brake failed to release or brake replacement.

F3 – Main motor

F4 – Tilt motor fault current too high or motor failure

F5 – Battery low or flat

F6 – Final limit switch activated, the lift has traveled past the normal stopping limit.

F7 – OSG or Overspeed governor device has been activated – never wind lift in the down direction.

F8 – Tilt limit leveling protection switch.

F9 – OSG pulse PCB failed to receive information.

C = CHARGING CODES

C1 – Lift is on a charging point and batteries are charging.

C2 – Charger is connected but the output voltage is too LOW.

C3 – Charger is connected but the output voltage is HIGH.

C4 – Lift is on a charge point and batteries are fully charged.

C5 – Batteries are rejecting charge voltage.

The 180, Acorn 80 and Bison Stairlifts

The Acorn 180 has evolved over the years from a few different brands and model numbers. Originally developed by Bison Stairlifts and acquired by Acorn in 2007 the lift has also been branded as the Bison 80 and the Acorn 80. While Acorn has kept the original modular rail design the latest 180 has a newer seat design and a few other changes. It’s important to note the older models will have a completely different circuit board, error codes, and batteries.